Akupanels (wood slat acoustic panels with PET felt backing) are widely used in offices, commercial interiors, and residential spaces for their ability to combine aesthetic warmth with acoustic performance. However, different wall substrates require different installation approaches to ensure long-term stability and optimal results.

In this guide, Leedings explains how to install Akupanels on drywall, concrete, and brick walls, including recommended tools, fixing methods, and best practices.

Understanding Akupanel Structure

Before installation, it’s important to understand how Akupanels work structurally:

Front layer: MDF or wood veneer slats

Backing: PET acoustic felt

Installation surface: wall substrate (drywall, concrete, or brick)

The PET felt backing allows flexible fixing options while maintaining sound absorption.

Tools and Materials You’ll Need

Akupanels

Measuring tape and spirit level

Pencil or chalk line

Construction-grade adhesive

Drill and screwdriver

Wall plugs (for concrete and brick)

Screws (recommended: black or concealed head)

Fine-tooth saw or utility knife

Installing Akupanels on Drywall

Drywall is the most common interior wall surface and offers the easiest installation.

Recommended Method

Adhesive + optional screw reinforcement

Step-by-Step

Clean the drywall surface and remove dust

Mark reference lines to ensure straight alignment

Apply construction adhesive evenly to the back of the PET felt

Press the Akupanel firmly against the wall

For large panels or high-traffic areas, add screws through the felt into wall studs

Tips

Always locate studs if using screws

Avoid overloading drywall with excessive panel weight

Adhesive-only installation is suitable for most residential projects

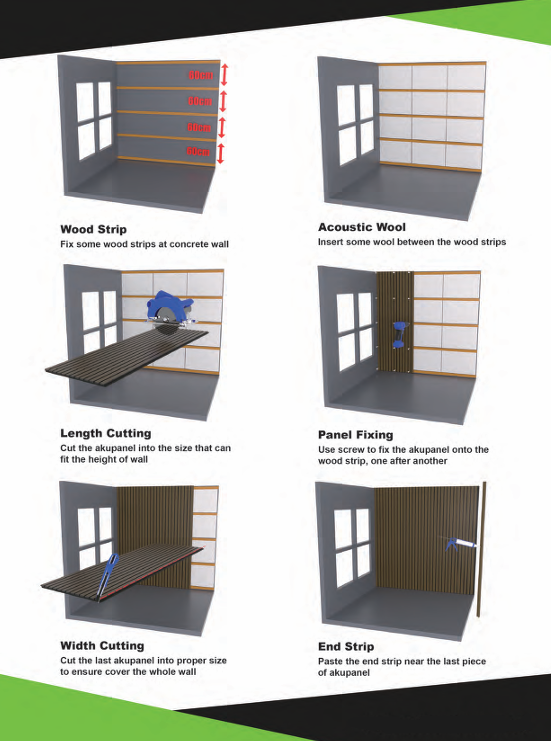

Installing Akupanels on Concrete Walls

Concrete walls are common in commercial buildings and require mechanical fixing.

Recommended Method

Screws + wall plugs (anchors)

Step-by-Step

Mark drilling points through the PET felt

Drill holes into the concrete wall

Insert appropriate wall plugs

Fix Akupanels using screws through the felt backing

Ensure panels are level before fully tightening screws

Tips

Adhesive alone is not recommended for concrete

Use vibration-resistant anchors in commercial environments

Screw heads remain visually hidden by the slat structure

Installing Akupanels on Brick Walls

Brick walls vary in hardness and require careful drilling.

Recommended Method

Screws + wall plugs

Step-by-Step

Drill into brick (not mortar joints if possible)

Insert wall plugs suitable for masonry

Fix panels through the PET felt backing

Adjust alignment before final tightening

Tips

Hollow bricks require specialized anchors

Avoid excessive torque to prevent brick cracking

Adhesive can be used as a secondary support only

Vertical or Horizontal Installation?

Akupanels can be installed:

Vertically for increased perceived height

Horizontally for wider spatial effect

The installation method remains the same regardless of orientation, but reference lines are critical for alignment.

Improving Acoustic Performance

To enhance sound absorption:

Leave a small air gap behind the panels

Combine Akupanels with additional PET acoustic panels

Use full-wall coverage in echo-prone spaces

Correct installation directly affects acoustic performance.

Common Installation Mistakes to Avoid

Using adhesive only on concrete or brick walls

Skipping wall plugs on masonry surfaces

Poor alignment of the first panel

Cutting panels from the front, damaging the veneer

Why Choose Leedings Akupanels?

Leedings Akupanels are designed for:

Consistent slat alignment

Durable PET acoustic felt backing

Compatibility with multiple wall substrates

Reliable acoustic performance in real-world installations

With advanced manufacturing capability and strict quality control, Leedings provides Akupanels trusted by architects, contractors, and interior designers worldwide.

Final Thoughts

Installing Akupanels on drywall, concrete, or brick walls is straightforward when the correct fixing method is used. By matching the installation technique to the wall substrate, you ensure long-term stability, clean aesthetics, and effective sound absorption.

For project-specific installation advice or technical support, the Leedings team is always ready to help.