In modern acoustic design, PET acoustic panels have become one of the most popular materials for noise control. Made from recycled polyester fiber, they combine excellent sound absorption, environmental sustainability, and flexible design possibilities.

But one critical factor determines how well they perform — density. The density of a PET acoustic panel affects how sound waves travel, are absorbed, and ultimately, how much echo is reduced in a space. Finding the right density means achieving the best balance between acoustic performance, weight, and cost.

In this article, we’ll explore how density influences sound absorption and share insights on choosing the perfect PET panel for your project.

1. The Science Behind Sound Absorption

Sound absorption occurs when sound waves enter a porous material and lose energy as heat due to internal friction. In PET acoustic panels, millions of microscopic air gaps between fibers act as energy traps — the denser the fibers, the greater the frictional resistance.

However, this relationship isn’t linear. Too little density allows sound waves to pass through easily, while too much density blocks them from entering at all. The goal is to find the “optimal density range” where sound waves penetrate just enough to be dissipated effectively inside the panel.

2. What Density Means for PET Acoustic Panels

PET acoustic panels are usually measured in grams per square meter (gsm) or kilograms per cubic meter (kg/m³).

Low-density panels (<1350gsm) are lightweight and good for high-frequency absorption but perform poorly at low frequencies.

Medium-density panels (1350–2200gsm) provide balanced absorption across frequencies and are most commonly used in offices, schools, and restaurants.

High-density panels (>2200gsm) become too compact, reducing airflow and limiting sound absorption improvements.

In tests following EN ISO 354:2003 and EN ISO 11654:1997, typical Leedings PET panels in this medium range achieve NRC values of 0.75–0.85, representing excellent performance for wall and ceiling applications.

3. Is There a “Peak Density” for Maximum Performance?

Studies and acoustic chamber tests show that sound absorption increases with density up to a certain point — typically around 2000–2200gsm — after which improvements plateau.

This plateau occurs because when fiber networks become too tight, the pore structure closes, preventing sound waves from entering deeply enough to be absorbed. In other words, the panel becomes more reflective than absorptive.

Therefore, beyond this range, the trade-off between cost, weight, and acoustic gain is no longer beneficial.

4. How Leedings Achieves the Perfect Density Balance

At Leedings Acoustic, all PET acoustic panels are engineered to deliver optimal performance across a broad range of frequencies. Our research and testing show that panels within the 1350–2200gsm range provide the best combination of absorption, stability, and durability.

Each Leedings PET acoustic panel undergoes strict quality control and is tested according to EN ISO 354, EN ISO 11654, and ASTM E84 Class A standards.

Leedings panels have an NRC up to 0.8, making them ideal for interior environments that require acoustic comfort — such as open offices, classrooms, studios, and public halls.

5. Practical Tips for Choosing the Right Density

When selecting PET acoustic panels for your project, consider these factors:

Room Type:

Large, echo-prone areas like conference rooms benefit from medium- to high-density panels. Smaller rooms or residential spaces can use lighter panels effectively.Installation Location:

For ceilings, use lighter panels to reduce load; for walls or partitions, medium-density panels perform best.Performance vs. Budget:

Once you reach optimal density, further increases offer minimal acoustic gain but raise material cost — choose the “sweet spot,” not the heaviest option.

6. Beyond Density: Other Factors That Matter

While density is important, it’s not the only factor affecting acoustic performance. Consider:

Panel thickness: Thicker panels (e.g., 24mm or 48mm) absorb lower frequencies better.

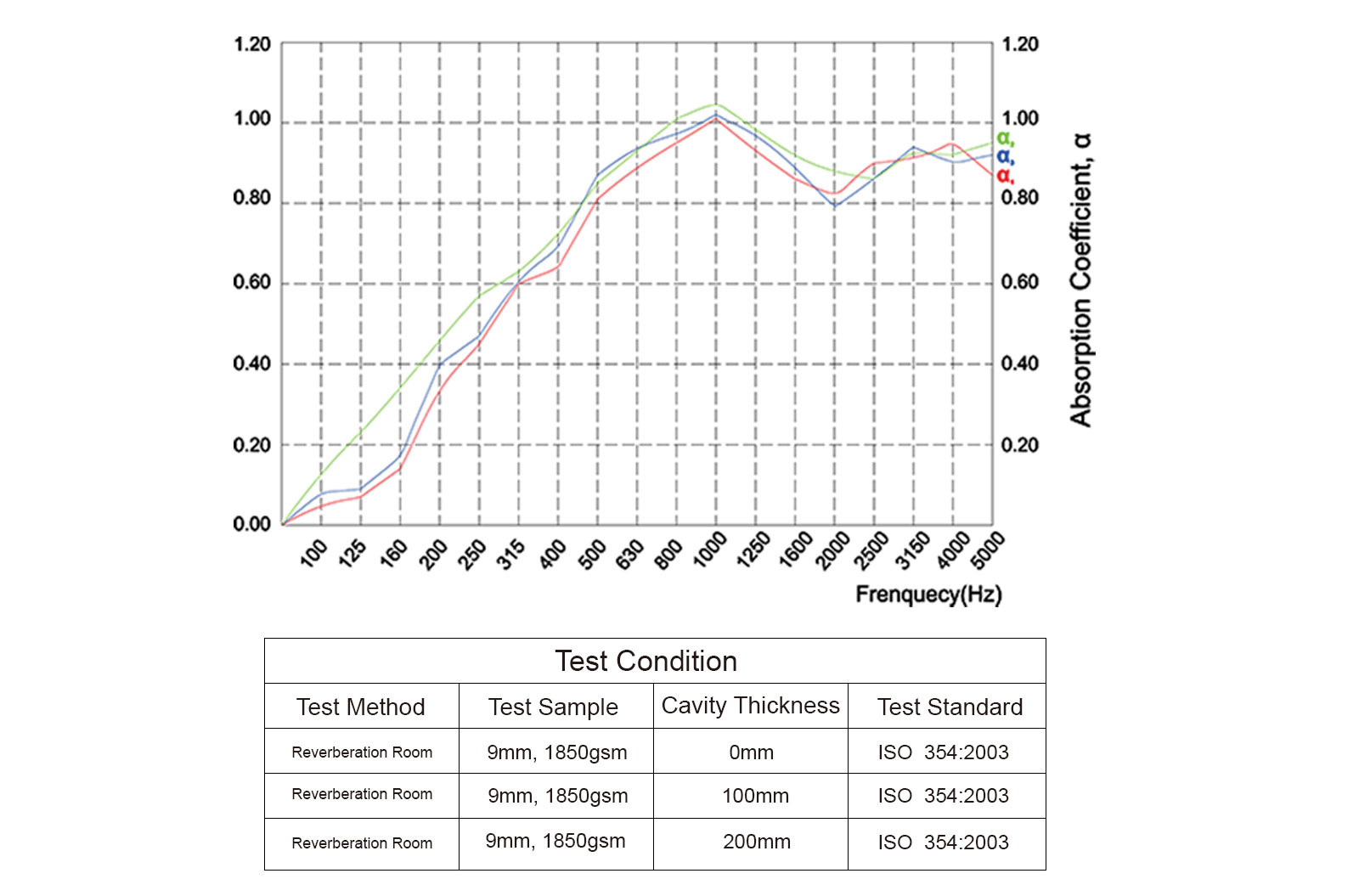

Mounting method: An air gap behind the panel significantly enhances absorption.

Surface texture: Perforations or embossed surfaces can improve high-frequency response.

Leedings provides full customization options for thickness, density, and finish to suit each acoustic design requirement.

7. Conclusion: Balance Is Key

The relationship between density and sound absorption in PET acoustic panels is all about balance. Too little density leads to weak performance, while excessive compaction limits airflow and acoustic efficiency.

Panels within the 1350–2200gsm density range consistently achieve the best results — combining high NRC values, durability, and eco-friendly design.

At Leedings, we continue to refine this balance through advanced material research and production technology, ensuring every panel meets the highest international standards for acoustic performance and safety.

About Leedings Acoustic

Leedings Acoustic is one of China’s leading manufacturers of polyester fiber acoustic panels (PET panels). With large-scale production capacity, cutting-edge technology, and certifications including CE, FSC, ISO 16000, ASTM E84 Class A, and EU-Class B (EN 13501-1), Leedings delivers high-quality, sustainable acoustic solutions to customers worldwide.

Explore our range of PET acoustic panels and discover how science and design combine to create quieter, safer, and more beautiful spaces.