Can Akupanels Be Cut Without Chipping the Wood Veneer?

Akupanels, also known as wood slat acoustic wall panels, are widely used in residential and commercial interiors for their modern appearance and excellent sound absorption performance. However, one common question from installers and project contractors is:

Can Akupanels be cut without chipping the wood veneer?

The short answer is yes — but only if the correct tools and cutting techniques are used. As an experienced acoustic panels supplier in China, Leedings Acoustic shares practical, proven guidance to help you achieve clean, professional cutting results.

Why Wood Veneer Chipping Happens

Chipping usually occurs due to one or more of the following reasons:

Using the wrong type of saw blade

Cutting from the wrong side of the panel

Applying excessive cutting speed or pressure

Poor panel support during cutting

Because akupanels combine wood veneer, MDF slats, and PET felt backing, they require a more controlled cutting approach compared to standard MDF boards.

Recommended Tools for Cutting Akupanels

To cut acoustic wall panels cleanly and accurately, we recommend the following tools:

Circular Saw or Table Saw

Use a fine-tooth blade (60–80 teeth) designed for wood veneer or laminated boards

Tungsten carbide-tipped blades deliver the best results

Track Saw (Preferred for On-Site Installation)

Provides excellent stability

Minimizes vibration and edge breakout

Ideal for precision cutting of long panels

Avoid rough construction blades, as they significantly increase the risk of veneer chipping.

Correct Cutting Direction to Prevent Chipping

One of the most important techniques is cutting orientation:

Always cut with the wood veneer facing downward when using a circular or table saw

This allows the blade to exit through the veneer cleanly, reducing tear-out

For installers working with akupanels, this single step can dramatically improve edge quality.

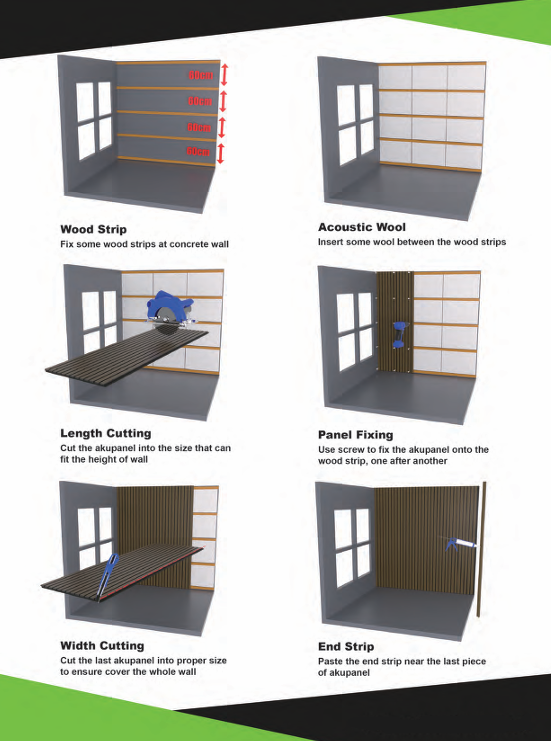

Step-by-Step Guide: How to Cut Akupanels Cleanly

Follow these professional steps recommended by Leedings Acoustic:

Measure and mark the cutting line accurately

Apply masking tape along the cut line to further reduce chipping

Secure the panel firmly to prevent movement

Cut slowly and steadily — do not rush

Lightly sand the edge if necessary using fine-grit sandpaper

This process works well for most acoustic panels from China, including standard and custom-size akupanels.

Can Akupanels Be Cut with Hand Tools?

While possible, hand tools are not recommended for cutting full panels:

Jigsaws often cause uneven edges

Hand saws increase the risk of veneer damage

For best results, power tools with proper blades should always be used, especially in commercial projects involving acoustic wall panels.

Factory Pre-Cutting vs. On-Site Cutting

As a professional acoustic panels supplier, Leedings Acoustic offers both options:

Factory pre-cut panels for large-scale projects

Standard-length panels designed for easy on-site cutting

For projects requiring perfect edges or complex layouts, factory pre-cutting is the safest solution to eliminate installation risks.

Why Choose Leedings Acoustic as Your Akupanel Supplier

Choosing a reliable akupanels supplier makes installation easier from the start. At Leedings Acoustic, we provide:

Stable, high-quality wood veneer

Consistent PET felt backing

Clear cutting and installation guidance

Custom sizing support for global projects

Our acoustic panels China manufacturing standards ensure that akupanels can be cut cleanly without compromising appearance or acoustic performance.

Conclusion

So, can Akupanels be cut without chipping the wood veneer?

Absolutely — with the right tools, correct cutting direction, and proper technique.

Whether you’re an installer, distributor, or project developer, following these best practices will ensure your acoustic wall panels deliver both visual excellence and long-term performance.

For technical support or customized akupanels, contact Leedings Acoustic, your trusted acoustic panels supplier in China.