If you’re working with polyester fiber acoustic panels, you’ve probably considered how to cut or engrave them for wall design, branding, or architectural detailing. Two common methods are CNC (oscillating blade) cutting and laser cutting. Each has distinct advantages and limitations depending on your project’s requirements.

We’ve worked with both methods in our manufacturing process and wanted to share insights based on real-world application. This might help you decide which suits your needs better.

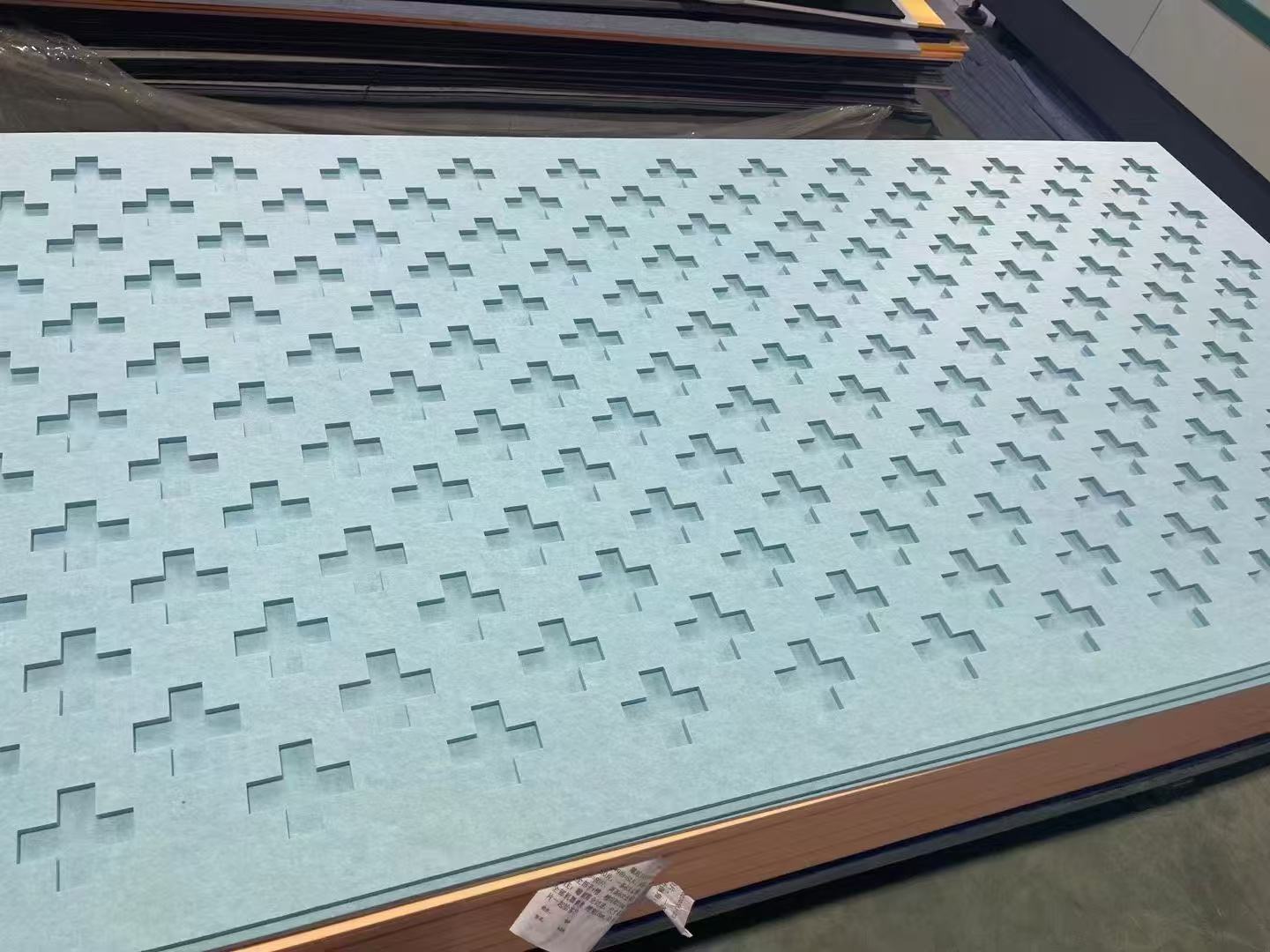

CNC (Oscillating Blade) Cutting

How it works:

CNC cutting uses blades to follow a CAD drawing and physically carve through the polyester board.

Advantages:

Clean, flawless edges and smooth cuts

No burn marks or discoloration

Ideal for medium to large patterns or straight lines

Works well for regular thickness panels

Limitations:

Minimum detail size is 10mm — blade cannot make ultra-fine cuts

Error tolerance is ±1mm, depending on product size

Not suitable for very small, tight patterns

Technical limits:

Minimum hole diameter: ~10mm

Maximum cutting thickness: 25mm

Deepest CNC engraving (keeping a base):

9mm thick board → max 6mm deep

12mm board → max 8mm deep

25mm board → max 20mm deep (leave 3–5mm base)

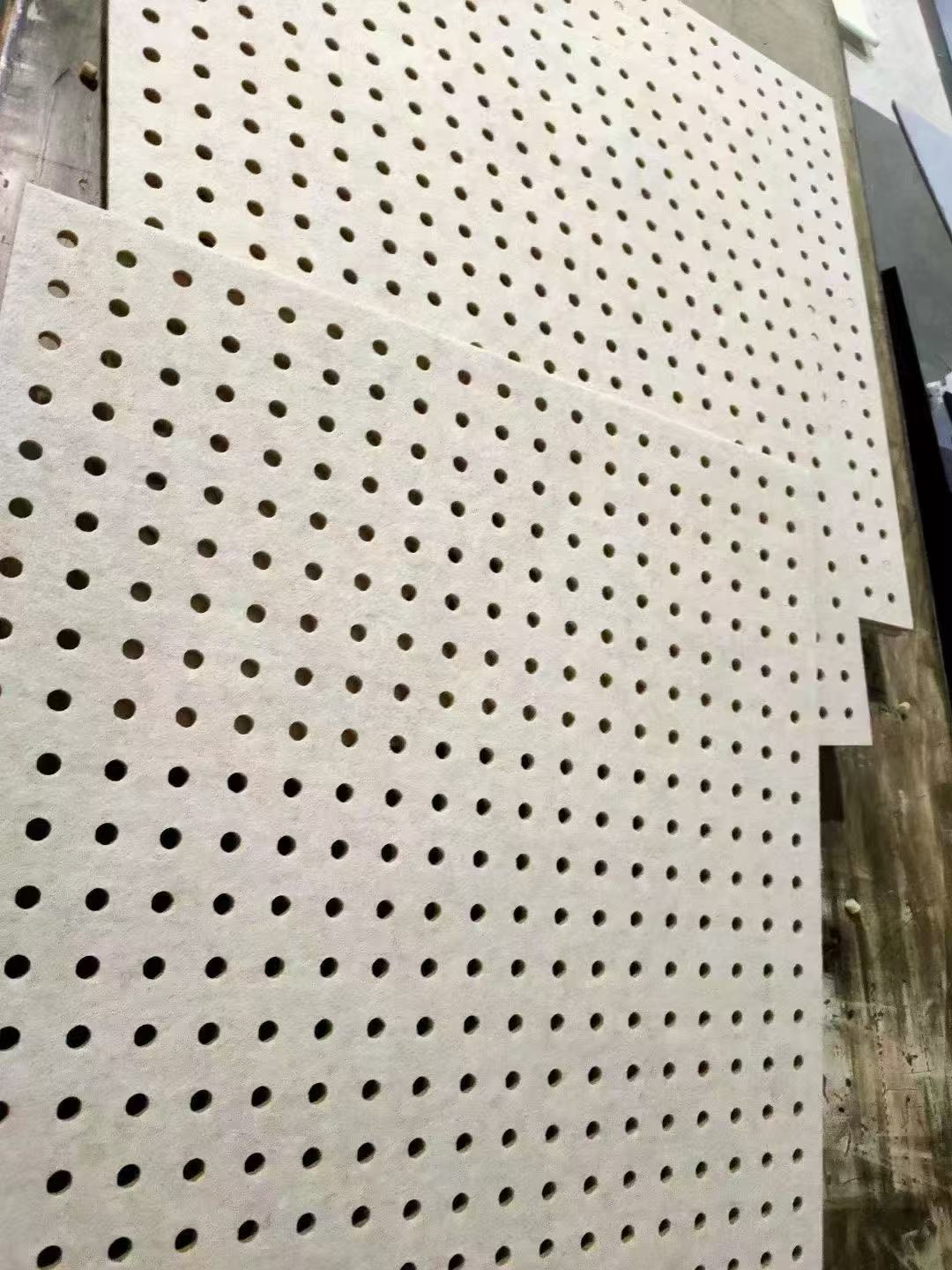

Laser Cutting

How it works:

Laser cutting follows CAD files and uses high-temperature lasers to burn through the material.

Advantages:

High precision — almost zero error

No shape or pattern size limitation

Excellent for logos, artwork, fine text, and custom design

Perfect for fast prototyping and detail-heavy projects

Limitations:

Burning edges / yellow discoloration due to heat

Polyester fiber contains thermoplastic additives that melt at ~120°C, causing edge charring

Not ideal for visible surfaces unless you plan to frame or paint the edge

Technical limits:

Minimum hole diameter: as small as 1–2mm

Maximum cutting thickness: 25mm (but slower on thicker boards)

Burn risk: Higher on thinner panels and on dense material

General Production Note

For both cutting methods, we recommend leaving 3–4mm base thickness during engraving. Polyester fiber panels are not always uniform in density, and going too deep may cause full penetration or surface distortion.

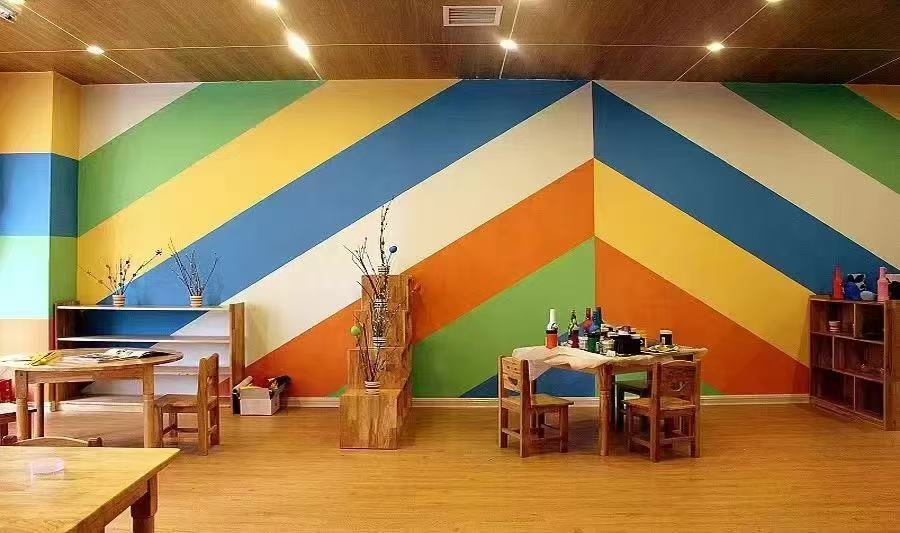

Application Examples

CNC cutting is ideal for:

acoustic baffles, geometric patterns, large panel designs

Laser cutting is ideal for:

branding, logos, art walls, custom-shaped acoustic panels

Learn More

If you’re interested in the technical details and see more examples of polyester fiber acoustic panels, feel free to visit our product page:

We specialize in acoustic materials with flexible customization, including CNC and laser finishing.

Let me know your experiences with either method — happy to answer questions or compare notes!